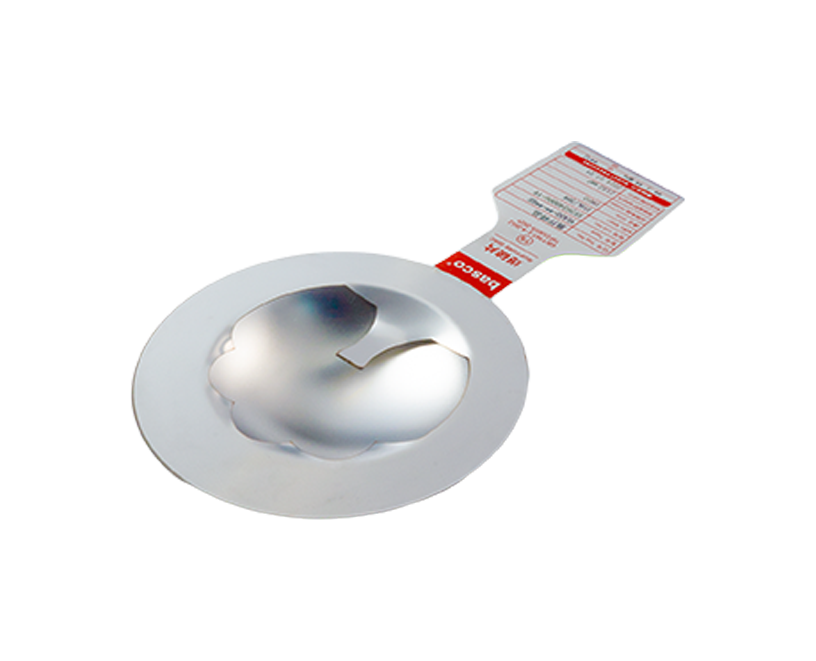

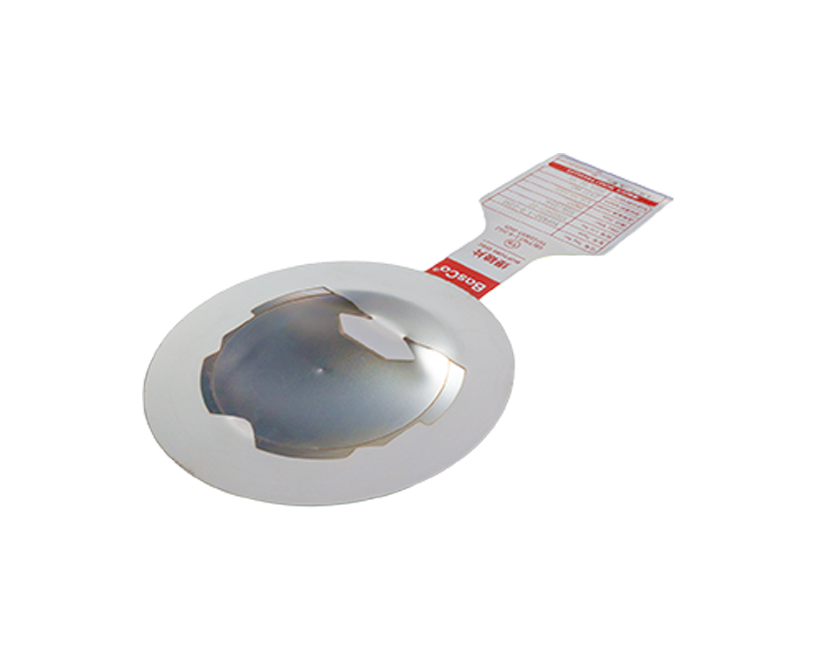

The YCP Rupture Disk utilizes an advanced technology of indenting the dome of the rupture disk to provide extremely accurate burst pressure control, while ensuring that it will open below the set burst pressure in the event of minor damage. The YCP is made of thicker and therefore stronger material than conventional rupture disks. A semi-circular attenuation groove is machined on the exit side of the rupture disk arch, which allows the rupture disk to destabilize and flip over to open along the attenuation groove at the edge when burst pressure is reached.

Options

Fluoroplastic lined or coated

BI Burst Sensor

*Note: The maximum temperature at which a liner, coating or BI rupture sensor can be used is lower than the maximum temperature at which the rupture disc can be used.

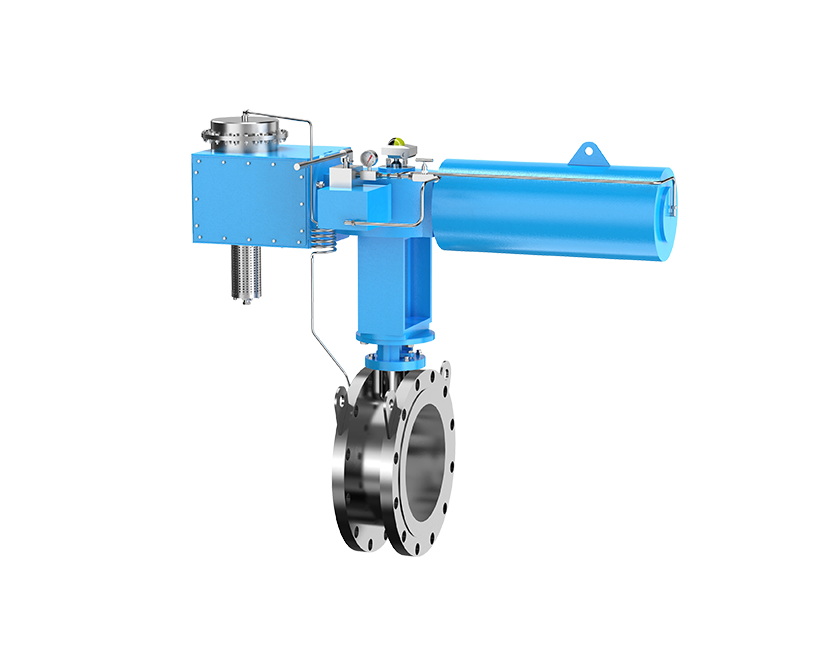

Safety Valve Protection

When installed on the process side of a safety valve, the rupture disc isolates the valve's working parts from corrosive media.

Relief components: short pipe, tee, pressure gauge, relief valve

Burst tolerance / (GB567-2012)

| Calibrated burst pressure bar |

≥0.01~<0.1 | ≥0.1~<1 | ≥1~<3 | ≥3~<1000 | ≥1000~<5000 |

| Bursting Tolerance | ±50% | ±25% | ±0.015MPa | ±5% | ±4% |