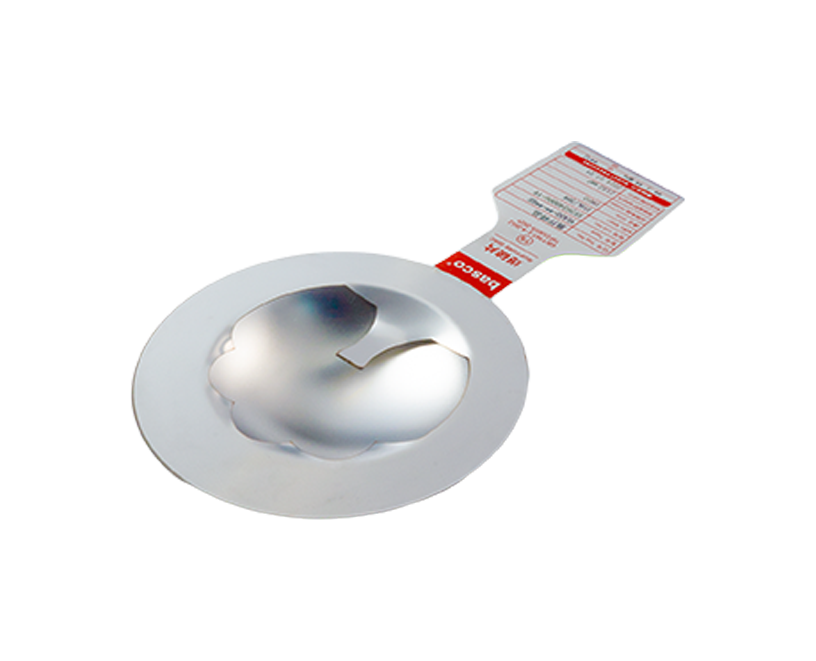

Flat Plate Open Seam Rupture Discs evolved from Positive Arch Open Seam Rupture Disks and come with their own gasket. Mainly used in low pressure applications and mounted directly into standard or simple flanges.

Available Options

Burst Sensors

Clamps

Fluoroplastic Gaskets

Rupture Disks for Tanks

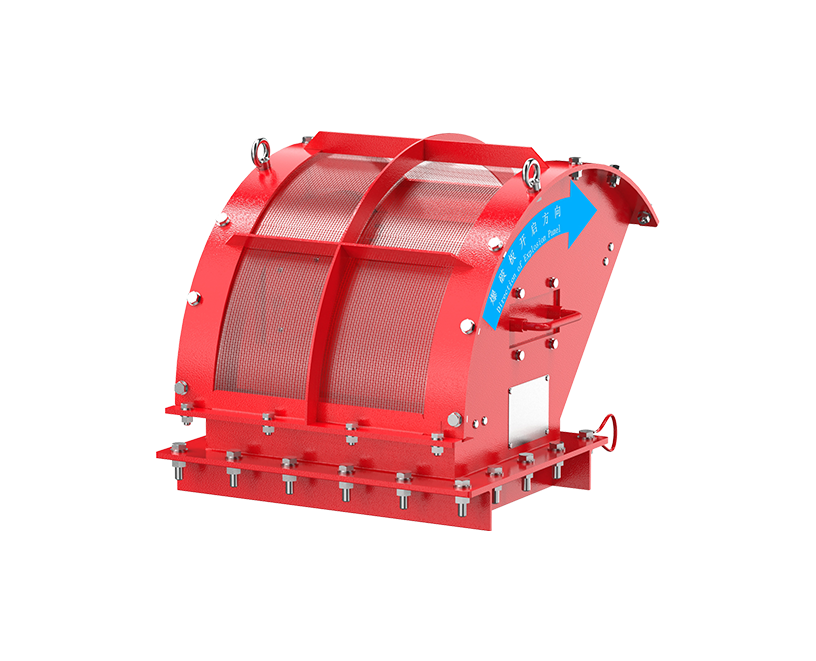

Tank Protection

Storage tanks are made of relatively lightweight materials and often have limited pressure holding capacity. If not properly relieved, a vacuum can easily develop, resulting in shell deflation and damage, and Type PF rupture disks can provide cost-effective protection for tanks.

The rupture disk size should be at least equal to the size of the tank's flow inlet or outlet connection, whichever is greater, the maximum burst pressure should be no greater than the tank's design pressure or vacuum, whichever is less, and the minimum burst pressure should be at least twice the tank's maximum working pressure or vacuum, whichever is greater.

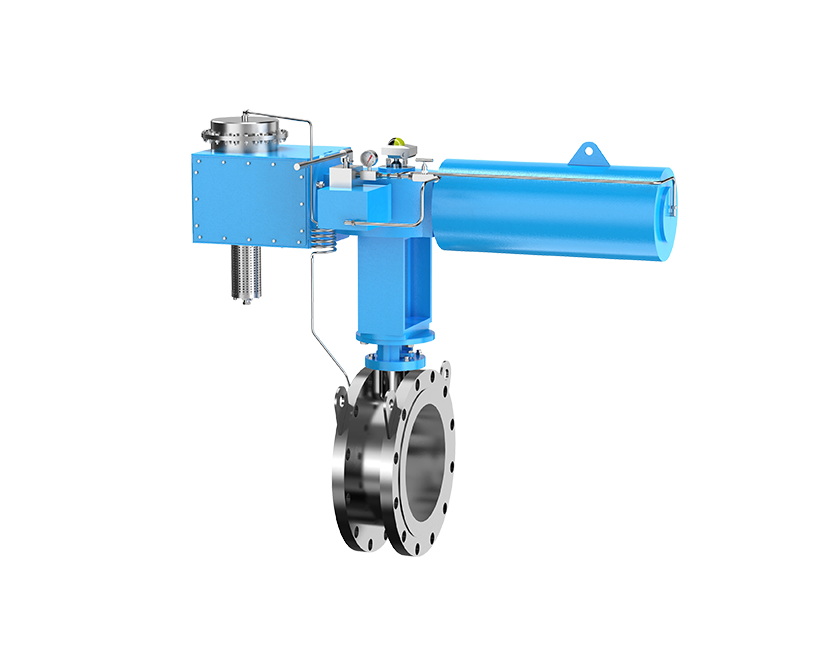

Pressure relief valve protection

Atmospheric corrosive substances entering the valve through the safety valve outlet are liable to damage the valve's working parts and affect normal operation, and valves whose outlets are connected to a common manifold are more susceptible to damage. A Type PF rupture disc mounted on the valve outlet flange will effectively protect the valve components from the harsh environment.

The rupture disk should be the same size as the outlet flange of the valve. The maximum burst pressure should not be greater than the set pressure of the valve and the minimum burst pressure should be at least twice the maximum working pressure in the manifold.

Burst Tolerance / (GB567-2012)

| Calibrated Burst Pressure bar |

≥0.01~<0.1 | ≥0.1~<1 | ≥1~<3 | ≥3~<1000 | ≥1000~<5000 |

| Bursting Tolerance | ±50% | ±25% | ±0.015MPa | ±5% | ±4% |