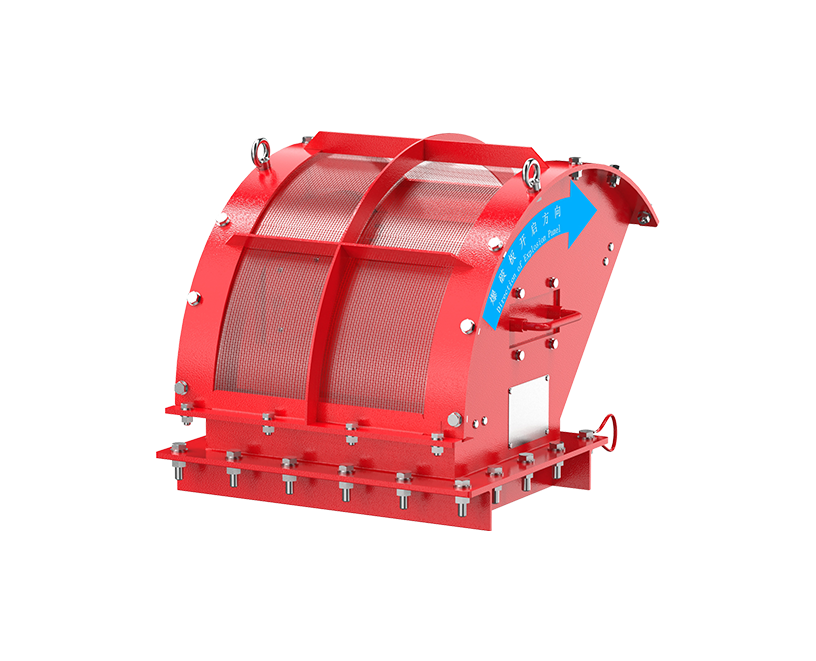

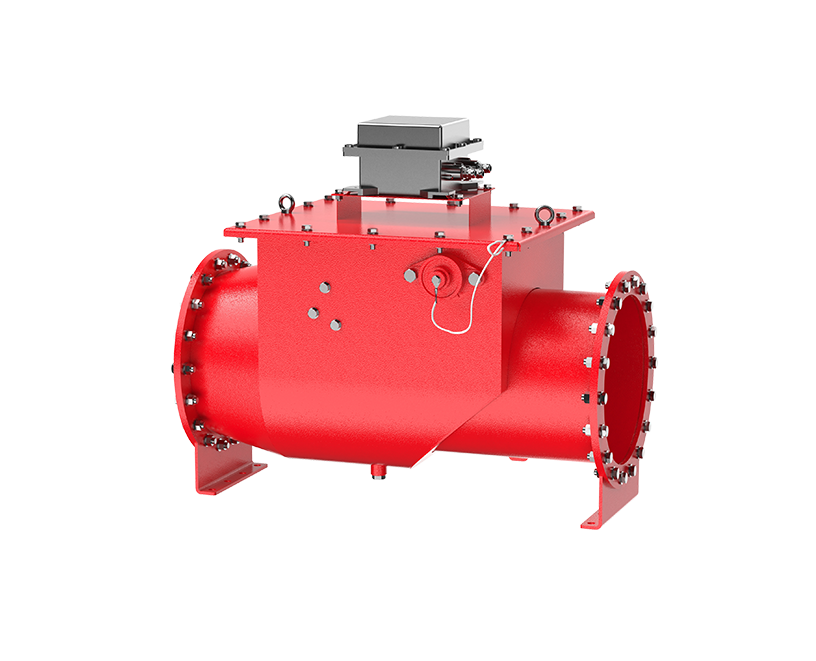

In reality, many containers are connected together, such as dust collector and pipeline, silo and pipeline, once an explosion occurs in a certain equipment, the flame and air pressure will be spread along the pipeline to other equipment, resulting in a secondary explosion or multiple explosions of the equipment. Setting the explosion-proof valve can effectively prevent the explosion from spreading, protect the neighboring equipment and workshop, and avoid causing secondary explosion or multiple explosions.

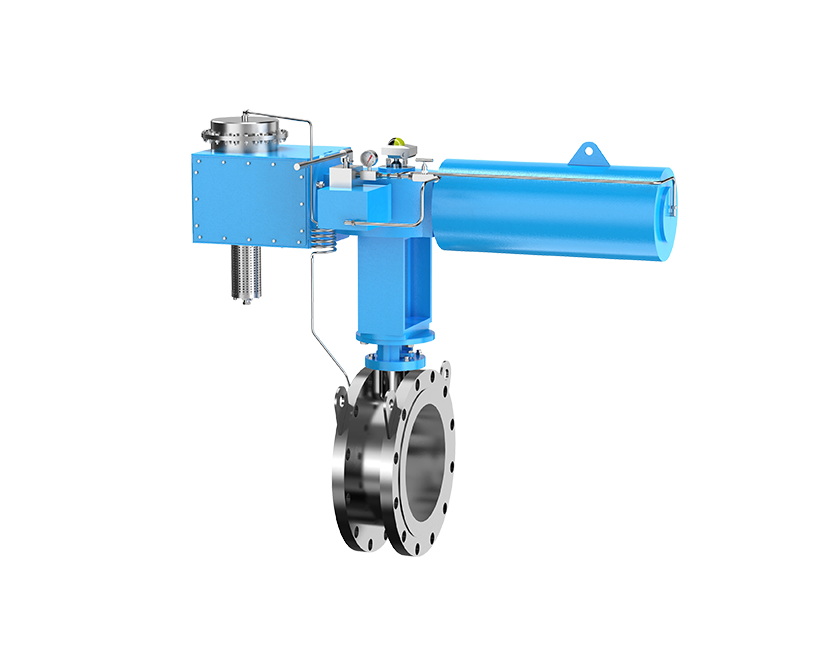

Working principle

When a dust explosion occurs, the shock wave in the flame front, the explosion-proof valve due to the explosion of the shock wave generated by the rapid closure of the valve, and locked by the self-locking mechanism to prevent the flame and pressure wave propagation, after the end of the explosion, the manual reset, simple maintenance and can be used again after evaluation. Normal operation, the valve flap is opened by the auxiliary opening device.

ACCESSORIES

Blast Sensor: HE

Use and Maintenance

It is important to ensure that the bursting valve is open before the system fan is operated to prevent damage to the fan and other equipment due to locking of the valve flap closure.

After installation and use, it should be overhauled at least once a month, and the number of times of overhaul can be increased according to the specific working conditions.

After overhauling and assembling, sealing test should be carried out and detailed records should be made for inquiries.