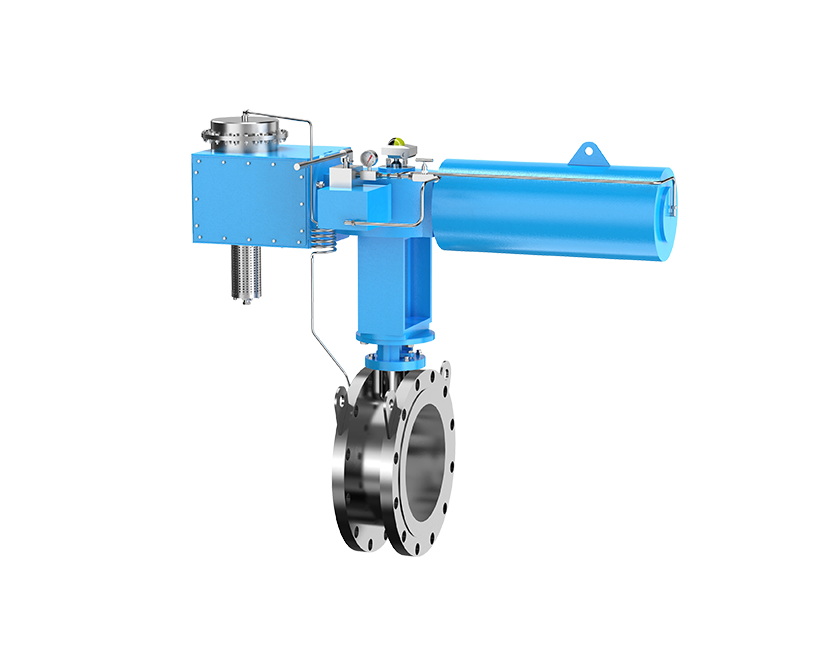

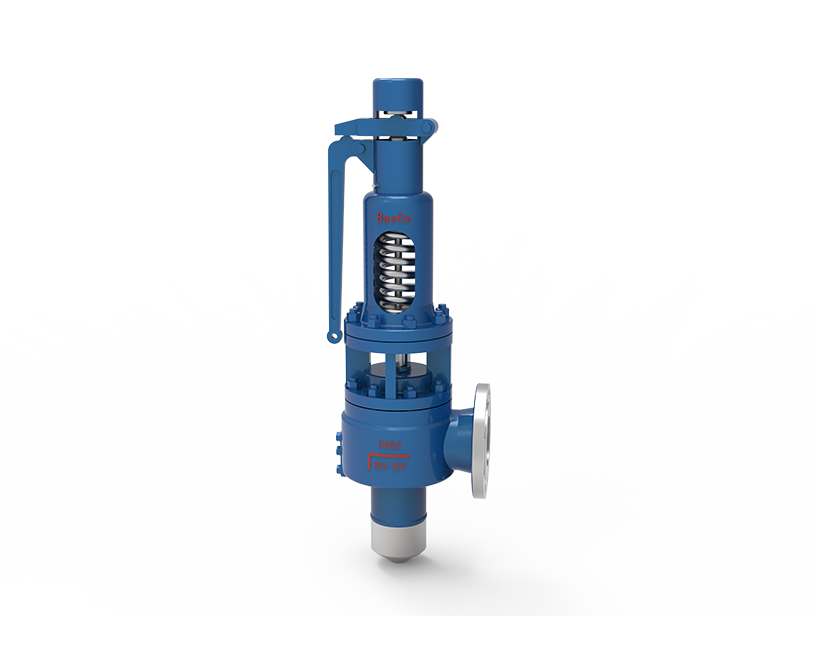

Usage

Mainly used in power station boilers, pressure vessels, temperature and pressure reduction devices to ensure the safe operation of equipment.

Installation instructions

1、Safety valve must be installed vertically, and it is best to install it directly on the connector of container or pipeline. The inner diameter of the joint should be not less than the inlet diameter of the safety valve.

2, the outlet of the safety valve must be equipped with appropriate expansion joints to prevent the thermal expansion of the discharge pipe to the safety valve to bring undue thermal stress. Discharge pipe diameter should be larger than the diameter of the valve outlet, the length as short as possible, to avoid bending. The weight of the discharge pipe and the expansion joint should not act on the safety valve and should be fixed on the building. The distance between the center line of the discharge pipe and the center line of the valve body should be as short as possible.

3. The outlet of the muffler should have enough area to prevent back pressure from affecting the discharge capacity of the valve.

4、The degree end of the discharge pipe and the bottom end of the valve body should be equipped with an evacuation pipe; the outlet of the back pressure adjustment sleeve must be equipped with a short bend.